The Real Cost of Low Cost

In our first blog on the impact of poor Side Lobes, we looked at how detrimental poor radiation pattern planning can be when it comes to performance. Now we take a closer look at the factors that can cause poor Side Lobes and the impact they have for customers.

Seeing the unseen: How compromise on the quality of antenna parts affect its performance

A microwave antenna is basically a passive mechanical device that has an electrical application and function. A well-performing antenna requires the assembly of several high-quality parts, as well as precise control over their mechanical dimensions during manufacturing and for their operational lifetime. The qualities of every constituent part of an antenna is highly relevant to its electrical performance, so compromises on the quality of these parts directly affect overall antenna performance.

The low-cost antenna suppliers, generally, compromise on the quality of various key components in order to reduce costs. These quality differences are not initially apparent to operators, but have severe effects on total system performance over time. Let’s look at this in more detail to shed some light on the importance of various antenna parts, and how they impact the overall performance of the backhaul system.

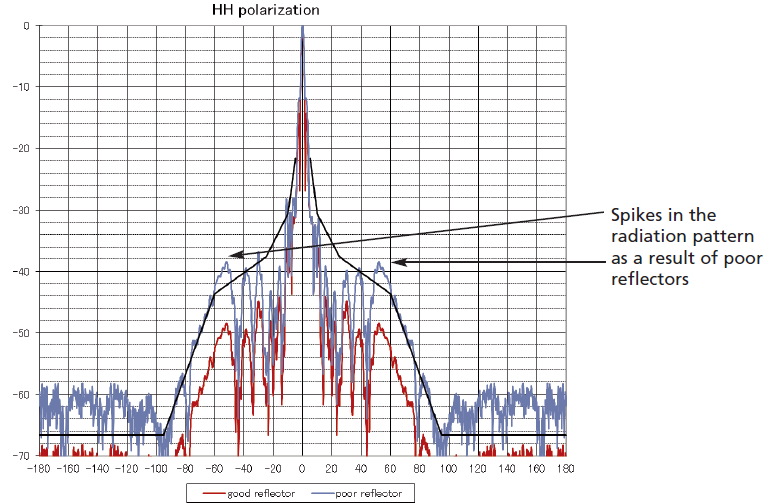

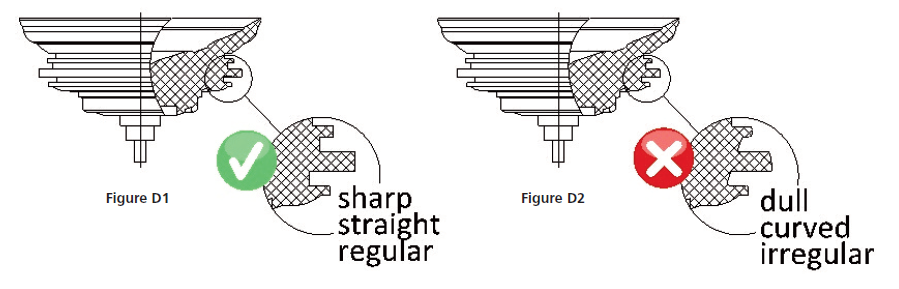

The reflector

All reflectors may look alike at first glance but the imperfect curve resulting from poor quality controls or unperfect packaging during transportation, directly impacts the radiation pattern of the antenna. The inconsistent curves of the reflectors result in unexpected spikes all over the radiation pattern.

The feed system

The quality of pipe in the antenna feed system directly impacts the antenna’s cross-polarization performance. The smooth finishing of pipe and proper concentricity are essential to achieve high XPD performance. A poorly manufactured pipe with rough finishing and improper concentricity may result in poor cross-polar discrimination (XPD) performance requested for XPIC. Only a very rigorous quality control and a “no compromise mindset” can ensure this is well respected

The Radomes

Radomes are used to enclose the antennas; their basic function is to form a protective cover between the antenna and the environment with minimal impact to the antenna’s electrical performance.

An ideal radome should have enough mechanical strength to protect from wind, rain and ice, and should be electrically transparent to deliver good RF performance. Considering these requirements, selection of radome materials is of utmost importance. Low-quality antenna manufacturers generally cut costs by compromising on radome quality and data sheets are often published without radome measurements. MNOs can therefore be easily misled, and ultimately receive lower field performance as a result. RFS chooses high-quality radome materials with low dielectric constant and dissipation factors, which minimizes various losses (insertion loss, reflection loss & absorption loss) and optimizes thickness to meet desired RF performances.

The real cost of “low cost”

The Total Cost of Ownership of a network backhaul system is driven by five key cost factors: frequency spectrum cost, transportation and logistics cost, installation cost, maintenance cost and operation cost. Out of these five key costs, the spectrum and maintenance costs are relatively high expenditures.

It can be tempting to opt for low-cost antennas. It reduces the CAPEX costs but operators are at high risk of falling victim to a false economy. They can create an overflow of signals, causing interlink interference and lowering the signal-to-noise ratio performance that ultimately produces lower capacity. To compensate the lower capacity, additional spectrum will be required to establish the link without interference, which will lead to higher total cost of ownership (TCO).

Low-cost antennas may appeal to operators considering their performance claims on the data sheets. However, as we discussed, their low performance quality significantly negates the initial cost benefits after only a few years of operation. The inferior antenna costs more to the network operator in terms of capacity and quality of service. It has been observed that a significant proportion of antennas do not comply with their published specifications, mainly the Side Lobe gain performance and cross-polar performance. The Side Lobe or off-axis gain performance degrades with time, which causes interference and affects the capacity of the link). It has a negative impact on quality of service as it restricts the ability to reuse the frequency spectrum, limiting the number of links that can be deployed for a given amount of spectrum, reducing operator’s revenue.

Additionally, low-cost antennas are more prone to rust and carry a risk of faster degradation because of the poor quality of hardware used for manufacturing. Due to poor design, inconsistent quality controls, and insufficient testing, low-quality antennas also carry a high risk of dropping out in the event of inclement weather conditions. The reality is that when operators factor in the cost of additional frequency spectrum, excessive expenditure on maintenance, and diminished product life of low-quality antennas, it is often a much smarter and cost-effective decision to buy quality upfront to avoid the spiralling OPEX costs that accompany low-cost antennas.

If you’d like to discuss how RFS can help design a backhaul system that is built with quality at its heart, get in touch with Benoît Bled, Product Line Manager Microwave Antennas Solutions.